ToyCarDealer.com, your Siku dealer since 2004.

If you are a customer from outside the EU, you can buy from us without VAT!

The webshop will only calculate your discount after logging in.

Rondleiding door de fabriek van Siku

It has been a while since we had a tour of the Siku factory in Luedenscheid. Of course, that is the big dream of every collector to take a look behind the scenes of the largest model car manufacturer in the world (they say themselves!). At the time, we had to pick up a large number of models with our bus for a large order. And since we were at the factory anyway, it seemed like an excellent opportunity to ask if we could take a look inside. During the ride there, we received a call with the great news that we would get a private tour. Of course, the rest of the ride was only incidental.

Arrival at the factory

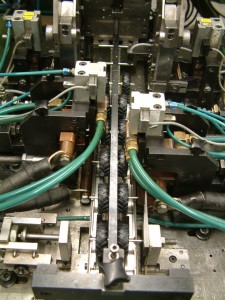

A rainy day and it was a bit of a search in the town of Luedenscheid when suddenly the familiar logo on a large building appeared after a gentle bend in the road. Finding a suitable parking space was also a bit of a challenge because the factory was being paved. But we were so close, the tension was palpable! It felt like a small child who is allowed to go to an amusement park for the first time. After registering at the reception, we were introduced to our representative who at the time managed the contacts and orders that came from the Netherlands. We had often spoken to her but we had never met each other. A gentleman who was going to lead the tour also joined us, and so we could start our tour. The front side of the factory has windows and there is room for all the administration and design departments. The photo above shows that the distribution and storage is on the bottom floor, via a staircase we reached the first floor and there were twenty machines that made plastic parts. Liquid plastic is pressed into a mold under high pressure and cooled immediately. Then the product falls onto a conveyor belt so that it cools even further and the part ends up in a collection bin. This is the so-called injection molding.

Plastic parts fall into a bin after production.

Example of a mold (right)

A hall further, it was not plastic that was melted, but zamac. Zamac is an alloy of zinc, aluminum and copper. Melting the zamac and injecting the liquid metal into the molds under high pressure was a lot warmer than the plastic versions, because in this hall it was quite sweaty! But certainly no less impressive!

At the back of the machines, pieces of zamac were manually placed in the ovens in blocks and on the other side a new part comes out of the machine about every 5 seconds. These trays are then sent to a department where the burrs are manually removed and all parts are also checked for defects. On the top floor it was very empty compared to the other rooms in the building. That is where the models were painted and printed.

The painting was also not as I expected. All parts were manually placed on special racks and very slowly these racks with parts went through a spray booth that did not apply paint, but a powder. This powder was then baked in an oven.

As you may know, powder can be very dangerous. It can be very explosive and these machines have sensors that immediately stop everything if a flash is detected. I took these pictures with a bad feeling because I had turned off the flash on my camera and kept a hand on the lamp, but you never know! And it was very expensive to get everything going again. Something you don't want on your conscience!

To my surprise I was allowed to take pictures and we could see how this works. In a corner of this floor was also the printing shop where we could see that a model can be provided with printing by two people at the same time. We noticed that this is also manual work.

The process is called pad printing. I will write about how it works in a separate post soon. In this department, parts were printed and then transported internally in containers, on these containers cardboard boxes were used as a cover. There were stacks of these cardboard boxes and my eye fell on a cardboard box with a very old print of Siku blisters! Together with the employees we looked to see if there were more in the stacks, but there appeared to be only one copy there. To my great joy I was allowed to have it, something very special of course!

The last department was the department where the tires and axles were assembled. In a large rotating machine, the tires were placed on the rims and then these wheels were pressed onto the axles with great pressure.

In this way, all the parts gradually came together to be able to make a complete miniature. Because Siku's production is now almost entirely housed in China, there is hardly any production in Luedenscheid anymore. Only when there is a rush delivery or when there is a shortage, they make some extra in Germany, the production line is then stopped after 12 noon.

After the tour of the factory, it was time to pick up our order in the warehouse, which was built just outside Luedenscheid. This is a robotized warehouse that is mainly set up vertically in order to gain as much space as possible.

Our bus was parked between the trucks at the shipping department and after we had been able to admire the robots, we saw our order ready on a large pallet. But because our bus has a much lower loading floor than the trucks, it was manual work again for the last time to load everything and be able to start the journey home. A very successful day to never forget!

Leave a comment

Log in to post comments

Comments

-

sikumuseum

By: Sikumuseum On 07/11/2016Siku produced untill a couple of years ago only in Germany, but started a production line in China.

The models where shipped unpainted to Germany and then transported to Poland for the paint-job.

After that the unboxed models where shipped again to Germany for inspection and packaging.

I know there is a change in this line, because there are a lot of models which are produced in Poland too, beside China.

I can imagine that the shipping from China to Germany takes too long for fast production if there is a shortage of a model. -

RiveraNotario

By: RiveraNotario On 07/01/2016What models are made in Germany? Bigger stuff like those 1:32 models, right? I thought no Super models were made in Germany, until last year I bought a VW Transporter Polizei that says that. Do you know why they keep some little portion of the production there?

-

Vanita Lenting-Diepnarain

By: Vanita Lenting-Diepnarain On 07/29/2015Vanita Lenting-Diepnarain liked this on Facebook.

-

Siku museum

By: Siku museum On 07/26/2015Siku museum liked this on Facebook.

-

Robert Ubink

By: Robert Ubink On 07/26/2015Robert Ubink liked this on Facebook.

-

Gracia Doekharan

By: Gracia Doekharan On 07/27/2015Gracia Doekharan liked this on Facebook.

-

Paula En Paul Kroll

By: Paula En Paul Kroll On 07/27/2015Paula En Paul Kroll liked this on Facebook.

Latest comments